TAU Systems joins programme to develop radiation testing for space-bound electronics

TAU Systems, the producer of ultrafast, compact laser-plasma accelerators, has announced its participation in a DARPA-funded initiative to develop new radiation testing capabilities for space-bound electronics. This programme, a part of DARPA’s Advanced Sources for Single Event Effect Radiation Testing (ASSERT) initiative, seeks to enhance the resilience of electronics deployed in space environments where exposure to cosmic radiation poses significant risks to performance and longevity.

The harsh conditions of space present a critical challenge for electronic systems used in satellites, spacecraft, and other space-based technologies. Single Event Effects (SEE) caused by high-energy cosmic radiation can disrupt or damage these systems, leading to catastrophic mission failures. Through DARPA's ASSERT programme, TAU Systems will contribute its expertise in producing the high-energy particle beams necessary for testing and evaluating radiation-hardened components, ensuring that the next generation of space electronics can withstand these extreme conditions.

DARPA's goal is to develop additional reliable sources for SEE radiation testing that can emulate the cosmic radiation encountered in space. TAU Systems, known for its cutting-edge particle accelerator technology, will support this initiative by developing a new, compact, cost-effective system that can simulate real-space conditions, allowing manufacturers and defence agencies to validate and harden their electronic systems against radiation-induced anomalies.

TAU Systems' involvement in the ASSERT programme represents a crucial step toward enhancing the overall robustness of space-bound electronics. The company will collaborate with NASA’s Jet Propulsion Laboratory, the Aerospace Corporation, UCLA, and RadiaBeam to develop and apply advanced radiation-hardened SEE testing methodologies. This effort will focus on developing and validating the eSEE (electron-based Single Event Effect) Testing concept.

"TAU Systems is honored to contribute to DARPA’s ASSERT programme, which will enable the US space industry to build more resilient systems for space exploration and defense," said Bjorn Manuel Hegelich, CEO and Founder of TAU Systems.

He continued: "As chips become more powerful and transistors become smaller, they also become more susceptible to cosmic radiation. To be able to use advanced computing and automation methods like machine learning (ML) and artificial intelligence (AI) in space, rigorous testing using advanced particle accelerators is essential to enabling new technology, protecting critical assets and ensuring mission success."

Bridging the gap in beam-time demand

Currently, the US has only four facilities capable of performing premium SEE radiation testing, summing to a total of about 5,000 hours of beam time per year – far below the estimated 30,000 hours demanded by academia and industry. TAU Systems’ compact design will generate between 2,000 and 4,000 hours of beam time annually per unit, greatly expanding access to critical testing.

SEE are disruptions in electronic components caused by high-energy particles, such as protons and heavy ions, which are prevalent in space. These particles can generate currents or voltage spikes that lead to temporary malfunctions or permanent damage. In critical defence and commercial satellites, SEE can interrupt communication, navigation, and data collection – vital functions that must remain operational in extreme environments.

Traditional radiation-hardened electronics undergo SEE testing using high-energy beams from large conventional ion accelerators to simulate the effects of space radiation. However, there is growing recognition that new, more advanced testing platforms are necessary to perform the requisite testing on advanced electronic systems. DARPA’s ASSERT initiative, along with TAU Systems’ advanced accelerator and beam delivery system capabilities, is designed to close this gap.

TAU Systems is a pioneer in compact particle acceleration technologies. Through its state-of-the-art particle acceleration technology, the company aims to provide critical SEE testing services to space electronics manufacturers, defence contractors, and other organisations focused on creating robust, radiation-tolerant systems. The data gathered from these testing campaigns will allow engineers to design stronger, more reliable systems that can operate safely and efficiently in space for extended periods.

"Understanding the effects of radiation in space is one of the most important steps in the design and development of resilient spacecraft," said Stephen Milton, Vice-President, Accelerator Science at TAU Systems. “DARPA’s ASSERT program leverages two key new technologies to emulate the effect of heavy ions on electronics, pulsed electron beams for single-event effects testing* and TAU’s ground-breaking Laser Wakefield Accelerator (LWFA) system that can precisely deliver a high-energy pulsed electron bunch to the device under test. Our system is significantly smaller and more cost-effective than conventional heavy ion test facilities; as such it can dramatically enhance the efficiency and accessibility of SEE testing. TAU is working with other key industry and university partners and together we believe such a new paradigm in SEE testing has the potential to revolutionise electronics testing capabilities and transform how space systems are prepared for the harsh radiation environments they encounter. With our expertise and DARPA's support, we are positioned to help industry overcome the challenges posed by cosmic radiation, ensuring that space missions can proceed without the risk of electronics failure."

How TAU System’s compact accelerator works

Particle accelerators hold great potential for semiconductor applications, medical imaging and therapy, and research in materials, energy and medicine. But conventional high-energy particle accelerators require plenty of space – some upwards of kilometres – making them expensive and limiting their presence to a handful of national labs and universities.

TAU Systems have built and rigorously tested a compact LWFA, which has a wide variety of applications, and the full system could be contained in a volume the size of a shipping container. In addition to testing how well space-bound electronics can withstand radiation, the accelerator technology will also be used to image the 3D internal structures of new semiconductor chip designs, and even to develop novel cancer therapies and advanced medical imaging techniques.

This kind of compact particle accelerator could also be used to drive another device called an X-ray free electron laser, which could be used as a light source for beyond EUV lithography for even more advanced chip production as well as being capable of recording the dynamics of processes on the atomic or molecular scale. Examples of such dynamic processes include drug interactions with cells, changes inside batteries that might cause them to go into thermal runaway, chemical reactions inside solar panels, and viral proteins changing shape when infecting cells.

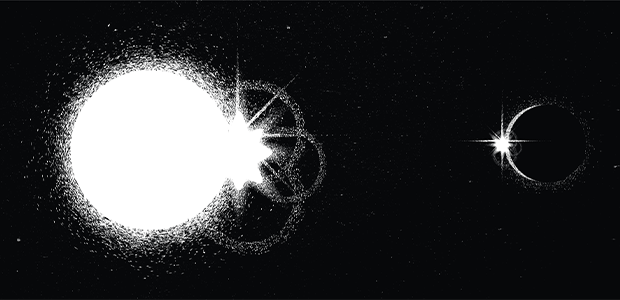

The concept for LWFA was first described in 1979. An extremely powerful laser strikes a gas target (e.g. Helium), heats it into a plasma and creates plasma waves that accelerate electrons from the gas, thereby generating a high-energy electron beam. Conceptually, the laser is like a boat skimming across a lake, leaving behind a wake – a plasma wake/wave – and electrons ride this plasma wave like surfers.

During the past couple of decades, various research groups have developed more powerful versions and Hegelich’s group holds the current record with a demonstrated acceleration gradient of over 100 billion volts per meter or 1,000x more than even the strongest conventional accelerators can achieve.

“It’s hard to get into the biggest wave without getting overpowered, so surfers get dragged in by Jet Skis,” Hegelich said. “In our accelerator, the equivalent of Jet Skis are metal nanoparticles that release electrons at just the right point and just the right time, so they are all sitting there in the wave. We get a lot more electrons into the wave when and where we want them to be, rather than statistically distributed over the whole interaction, and that’s our secret sauce.”

For more startup news, check out the other articles on the website, and subscribe to the magazine for free. Listen to The Cereal Entrepreneur podcast for more interviews with entrepreneurs and big-hitters in the startup ecosystem.