How to tap into the multi-billion-dollar machine vision market

Inspekto has released a whitepaper on the future of quality assurance in the industrial automation market. The paper addresses the needs of automation vendors and distributors who wish to add the first off-the-shelf product for industrial vision inspection to their portfolio.

Industrial automation vendors provide their customers with all the equipment and components they need to automate their plants - from PLCs to motors, from cables to HMIs. Through their efficient corporate distribution channels, automation vendors can quickly deliver their products, ensuring that end-customers get what they need in a matter of hours.

However, there’s one thing that they usually can’t deliver - solutions for quality inspection. Traditionally, machine vision solutions for quality inspection required the case-specific integration of numerous components including lenses, lighting equipment, frame grabbers and software, which have to be chosen and assembled by a systems integrator. As a consequence, automation vendors can offer the components to assemble a machine vision solution, but not the solution itself.

The advent of Autonomous Machine Vision changes the status quo, allowing automation vendors to tap into the multi-billion-dollar machine vision market, for the first time in history. It is this turn of events that Inspekto’s whitepaper explores.

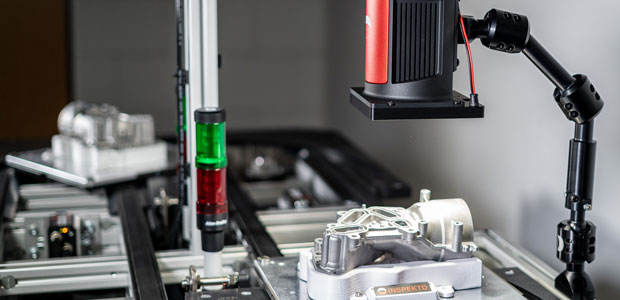

“The first Autonomous Machine Vision system on the market, the INSPEKTO S70, is actually a standalone product, ready to use out of the box, like a laptop or a smartphone,” explained Harel Boren, CEO and Co-founder of Inspekto.

“It requires no integration and can be installed by any employee, without external support, in 30 to 45 minutes. As a consequence, it fits the broad distribution model typically adopted by industrial automation vendors.”

The new whitepaper, available for free download on Inspekto’s website, explains the limits of traditional solution for industrial vision inspection. Through a wide array of data, quotes and statistics, it demonstrates why these solutions are not compatible with the distribution model of automation vendors.

The paper goes on to describe the characteristics of the only alternative on the market - Autonomous Machine Vision. It ends with a comprehensive overview of the size and potential of the machine vision market for quality inspection, a space that automation vendors can now finally explore.

“The efficiency, affordability and ease of installation of Autonomous Machine Vision products will finally unlock the potential of the machine vision market, burdened by the complexity and high-cost of traditional solutions,” concluded Boren.

“Autonomous Machine Vision marks a new era for industrial automation, the era where visual inspection takes its rightful place as a member of the industrial automation family.”

The paper is available to download for free from the company’s website.