Gravis Robotics secures $23M to accelerate global growth

Gravis Robotics has announced a new wave of industry partnerships alongside $23 million in fresh funding.

Gravis Robotics’ systems are already used by industry giants in construction, and for the autonomous handling of quarry materials with Holcim and others – supporting site preparation, stockpile management, and the loading of trucks and screeners. Most recently, Gravis Robotics broke ground at a Taylor Woodrow infrastructure project at Manchester Airport – the UK’s first large-scale use of autonomous excavation on an active construction site.

Gravis is also now partnering with the UK’s largest plant hire provider Flannery to provide a combined rental package for construction customers, enabling a turnkey excavator solution that is already equipped with the Gravis Rack. A similar model is available through the dealer networks of Gravis’ OEM partners, where its Develon-integration has been deployed in the UK, and most recently with Kibag in Switzerland.

Following this expansion, Gravis is now live in seven countries across the UK, EU, US, LATAM, and Asia – one of the widest footprints for autonomous excavation technology in the world, spanning mixed-fleet and OEM-integrated equipment. It also sees Gravis bring autonomy directly into the earthmoving equipment rental market for the first time.

And now, with its latest funding, Gravis has the technology, partnerships, and industry-wide, global distribution channels in place to lead the rollout of true autonomy at scale.

Founded in late 2022 as a spinout from ETH Zurich, Gravis is tackling construction’s biggest challenges – rising demand, falling output and an ageing workforce – by targeting productivity, not processes.

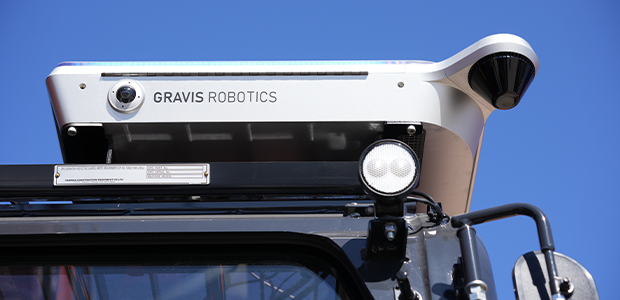

Drawing on the team’s deep expertise in AI and autonomy, the retrofit system goes far beyond simple commands. It adapts to real ground conditions through a learning-based control system that “feels the soil” using data from hydraulics, LiDAR, cameras and GNSS. This intelligence is paired with Gravis Slate – a tablet interface designed to fit seamlessly into construction workflows, that uses the robotic sensor suite to also augment manual operations – creating a continuous data loop that helps Gravis improve performance and expand its autonomous capabilities at speed.

Purpose-built to handle the unpredictability of sites across a range of tasks, from trenching and earthworks to grading, material handling and more, Gravis enhances human teams rather than replacing them, boosting output 30%, reducing rework, and improving safety. One partner, Morgan Sindall Construction described Gravis’ robotic excavator “as productive as a skilled machine driver – and in some instances, enhanced team efficiency.”

Ryan Luke Johns, Co-Founder and CEO, Gravis Robotics, said: “The fastest path to autonomy is delivering productivity today. By giving operators real-time 3D intelligence and the ability to shift seamlessly between autonomy and augmented control, we cover more of the work, accelerate adoption, and create the data pipeline needed to learn new capabilities from the industry’s hardest jobs.”

Archie Muirhead, Partner at IQ Capital said: “Gravis stands out, not just for its technical brilliance, but for how much it’s already achieved. The team’s thoughtful, grounded approach to autonomy – deploying real systems with real crews – has led to trusted partnerships with some of the largest global construction companies and OEMs and invaluable data from time-in-field. This huge and unserved market is ready now for autonomy and Gravis is setting the pace.”

For more startup news, check out the other articles on the website, and subscribe to the magazine for free. Listen to The Cereal Entrepreneur podcast for more interviews with entrepreneurs and big-hitters in the startup ecosystem.