Ecodesign regulations for power supplies give startups the edge

In the next of our series of Technology Briefings for entrepreneurs, we show how ecodesign regulations for electrical systems can present startups with a competitive advantage over established players. Compliance often demands fundamentally different approaches and technologies for power supplies, which can be easier to address when starting with a ‘blank sheet of paper’ than when evolving an established product.

This article originally appeared in the November/December issue of Startups Magazine. Click here to subscribe

Authors: John Bowman, Marketing Director and Andrew Pockson, Divisional Engineering Manager, at Anglia Components

New regulations to improve the efficiency of electricity-consuming appliances present a real opportunity for startup businesses. Regulators are now setting extremely aggressive ecodesign targets for power supplies – such as the latest European requirement for server products to satisfy 80 Plus Titanium. These are so demanding that they are on the verge of becoming impossible to satisfy using ordinary silicon-based power electronics. It’s time to change, and fortunately, new technologies like silicon carbide (SiC) and gallium nitride (GaN) can offer a solution.

Innovators that can get to grips with these devices, and the new design approaches they require, have an opportunity to gain a first mover advantage in new products ranging from small accessory chargers and power adapters for all kinds of domestic electronics to industrial power supplies and server-room equipment SiC and GaN, also known as wide-bandgap semiconductors, exhibit much closer to ideal switching behaviour than conventional silicon power MOSFETs and IGBTs. Their energy efficiency is also greater in the conducting phase. These advantages enable switched-mode power converters to achieve far greater energy efficiency across the load range and consume less standby power. Moreover, the superior switching performance allows designers to use higher operating frequencies than are feasible with silicon devices and hence they can select smaller passive and inductive components to stabilise the output. It also becomes possible to use novel components such as planar transformers, which are manufactured as part of the PCB substrate and occupy much less space than conventional wirewound transformers. As a result, power supplies can be smaller, run cooler, and meet increasingly stringent ecodesign targets.

Wide bandgap has landed

Manufacturers like ROHM Semiconductor and STMicroelectronics (ST) have already released several generations of SiC components, while ST and Efficient Power Conversion, Inc. (EPC) are among the go-to manufacturers for GaN. Energy-conscious products using these devices are entering the market now. Broadly, SiC addresses high[1]voltage applications such as eMobility including electric vehicles and charging points, as well as industrial power supplies and inverters for renewable energy generation. SiC also has very good performance at high temperatures. GaN is considered for lower voltages, although the ratings of the latest GaN power transistors, a.k.a HEMTs (high electron mobility transistors), show a trend rising towards SiC territory. GaN can allow faster switching speed, smaller form factor, smaller heatsinks, and easier cooling.

Design with wide bandgap technology

Markets for power supplies and converters based on these wide-bandgap technologies are still relatively new and the competitive situation is in flux. It’s a great time for organisations that have power design expertise to enter and be disruptive. GaN, especially, is carving out its territory and looks set to dominate in applications such as consumer equipment and power adapters, medical power supplies, data centre converters, class-D audio, and some automotive applications. In addition, GaN’s fast switching speed, which gives an excellent dynamic response, enables envelope-tracking RF power amplifiers to significantly cut the power demand in systems like 5G base stations and extend the runtime of mobile handsets.

The new devices can be used with conventional power-converter architectures to deliver a direct improvement in efficiency and standby power. On the other hand, they also create scope to explore novel topologies like active-clamp circuits that can simplify design and deliver greater efficiency.

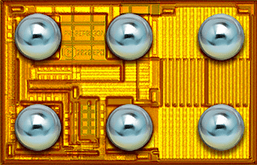

Wide-bandgap gate-drive requirements differ from those of ordinary silicon. SiC devices need a higher turn-on voltage and respond best with a negative turn-off voltage, while GaN devices need very high-speed gate signalling. Using an optimised gate driver IC, or integrated modules such as ST’s MasterGaN devices that put a complete two-transistor bridge with gate drivers in a single package, can alleviate design challenges and accelerate time to market. At Anglia, of course, we can help you choose the best components to meet your needs and design them into your next generation of power supplies and converters.

Latest tech off the shelf

On the other hand, companies that incorporate off-the-shelf power supplies into their own products can gain a competitive advantage by changing to new models that are based on wide-bandgap technologies. This could be a relatively straightforward decision to purchase a different type of external power adapter, to be simply packed in the box alongside the end product ready for shipping. Soon, this will be necessary to achieve mandatory product-level certifications such as CE marking. Right now, making the investment can deliver marketing benefits, and a better efficiency rating for products such as home appliances or PCs that are subject to energy labelling regulations. Smaller sizes and easier thermal management allow design teams to create new products that are slimmer, less intrusive, and more pleasant to use in the home or in a hot office or factory environment, than the competition’s. You can promote these properties as unique selling points.

Conclusion

In the automotive industry, the move from fossil fuel-powered to electric vehicles has provided a window for new entrants into the market like Tesla. The same dynamic can apply in other markets too, where a legacy design with established technologies can become a hindrance rather than an asset. Whether you’re a startup or an established player, the next generation of power technology is here and the time to adopt it is now. Whether you are a power product design company, or incorporating off-the-shelf units into your own products, there is still time to be among the early adopters. Incoming ecodesign regulations will soon require everyone to make the switch. Wide-bandgap technologies will be at the forefront of the new energy age and certainly among those that will be instrumental in making all our lives more pleasant as well as enhancing sustainability.