SAEKI raises $6.7M to transform large-scale manufacturing

With global supply chains facing mounting pressures and costs continuing to rise, manufacturing is at a critical juncture. Industries like aerospace, automotive, and construction face long lead times and high costs for large-format components, relying heavily on fragmented supply chains and labour-intensive processes. Manufacturing automation business SAEKI announced a $6.7 million funding round to address these challenges through its innovative approach to digital manufacturing.

The seed round was led by Lightbird with participation from Founderful, 2100VC, Danobat, and multiple high-profile business angels.

Unlike traditional manufacturers who rely on manual processes, SAEKI combines large-scale additive manufacturing with precision CNC machining in a unified production system. This hybrid approach enables the company to deliver precision-engineered components in days rather than weeks, while maintaining the highest quality standards through automated inspection processes. By incorporating automated quality assurance, the company ensures every part meets stringent industry standards, enabling faster delivery times and improved cost efficiency for large-format components.

SAEKI is also announcing the launch of its breakthrough instant quoting platform, enabling customers to upload designs, configure requirements, and receive immediate pricing for precision-engineered parts. By eliminating traditional quoting bottlenecks, SAEKI has reduced the procurement cycle from days to minutes.

“There's an exponential and widening divide between what we can design and what we can actually build,” commented Andrea Perissinotto, Co-Founder and CEO of SAEKI. “While engineers can now use AI to create hundreds of optimised designs, legacy manufacturing simply can't deliver these components cost-effectively. By automating the entire process, from quoting to final inspection, to make these advanced designs manufacturable at scale. Our mission at SAEKI is to make manufacturing faster, more efficient, and more reliable. By integrating additive manufacturing with CNC machining and quality assurance, we're giving industries the tools they need to innovate without constraints. This isn't just about making parts; it's about reshaping the way industries approach production. This is a defining moment for European manufacturing as we set out to build a future with fully autonomous factories.”

SAEKI’s origins are deeply rooted in hands-on manufacturing experience. The company’s CEO Andrea Perissinotto began his journey in his uncle’s workshop, where he witnessed firsthand how traditional production relied heavily on scarce, highly skilled craftsmen with decades of experience. “We saw an opportunity to integrate advanced manufacturing technologies to overcome these limitations and scale production efficiently,” said Andrea Perissinotto. “The existing processes demand decades of experience and are incredibly hard to scale. With AI and robotics, we’re now able to abstract and automate these skills.”

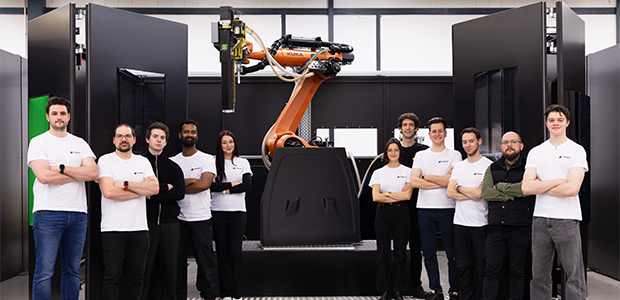

SAEKI was founded by Andrea Perissinotto (CEO), Oliver Harley (CTO) and Dr. Matthias Leschok (COO), during their studies at ETH Zürich. The trio identified a unique opportunity to bring industrial-scale efficiency to large-format additive manufacturing and CNC machining, making the process faster and more cost-effective.

SAEKI's technology-driven approach not only reduces waste and shortens lead times, but also helps reshore critical manufacturing capabilities to Europe. Moreover, by minimizing reliance on overseas suppliers, the company aligns with broader industry trends toward sustainability and supply-chain resilience.

The opportunity for SAEKI and the entire industry is immense. In meetings, one of the largest Swiss construction groups said the country would need another 3-4 SAEKIs to meet the potential demand for their formwork products. While a global automotive manufacturer noted that using SAEKI’s 3D-printed composite tooling shaved 2 weeks off of their production schedule. The sheer speed of delivery, 1 week vs 6 weeks from traditional suppliers, presented a significant opportunity.

“The company’s focus on large-format manufacturing is particularly timely, as sectors like aerospace and construction face increasing demand for complex, high-performance parts,” said Thomas Meier, Partner at Lightbird. “Global supply chains are under pressure, with rising costs and delays becoming the norm. We believe that SAEKI’s ability to deliver high-quality components quickly and reliably sets a new standard for the industry.”

The investment will accelerate SAEKI's development of autonomous factories that integrate quoting, 3D printing, machining, and inspection into a seamless process. "We share SAEKI's vision of European dynamism and strengthening Switzerland's manufacturing position," said Alex Stöckl, Partner at Founderful. "Their interdisciplinary team has shown remarkable progress, demonstrating the potential to reshape industrial production."

For more startup news, check out the other articles on the website, and subscribe to the magazine for free. Listen to The Cereal Entrepreneur podcast for more interviews with entrepreneurs and big-hitters in the startup ecosystem.