Monumo: electric motors designed differently

For over a century, electric motors have been designed in much the same way. Their efficiency has improved incrementally, but at their core, they remain a collection of individually optimised components, bolted together. But every dog has its day, as they say, and Monumo is challenging this approach by using deeptech AI to reimagine the motor systems as a whole. The result? Higher efficiency, lower costs, and a reduction in the use of rare earth materials – achievements that have not been possible before.

This article originally appeared in the March/April 2025 issue of Startups Magazine. Click here to subscribe

At the heart of Monumo’s innovation is the belief that motors should be designed holistically rather than as an assembly of separate parts. Dominic Vergine, CEO and Co-Founder, explains: “A motor by itself is a paperweight. It can't do anything without the rest of the system … and those components are all designed separately for something that is fundamentally a really symbiotic system.”

By taking a systems-level approach, Monumo is proving that every single parameter in an electric motor can be greatly improved. From material use to cost, efficiency, and sustainability, the company is making gains that others have struggled to achieve.

The journey to Monumo

Vergine’s career has always centred around new ideas, technology, and impact. A multi-startup founder, he spent 12 years at ARM, where he built the company’s sustainability function from scratch. It was during his time at ARM that the initial idea for Monumo emerged. In 2010, he led an innovation project, ‘ARM 2020,’ which examined technologies that could drive new markets a decade into the future. One area stood out: electric motors.

“We looked at how, essentially, the potential of computer processing has always just been bolted on. It's never been designed into motors, and it still isn't really today,” Vergine recalls. “They haven't changed hugely in 100 years.”

And so, in 2021 – almost exactly a decade after that initial research – Monumo was born.

What makes Monumo different?

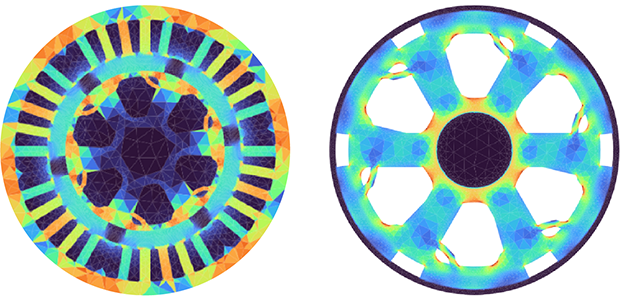

What sets Monumo apart is its ability to simulate thousands of design parameters simultaneously. “The big differentiator, what allows this to now be possible, and it probably wasn’t possible in 2010, is the speed of simulation,” says Vergine. Traditional motor design involves optimising individual parts before assembling them into a final system. This means engineers can only refine components in isolation. Monumo’s AI-driven approach analyses every aspect of a motor at once and identifies optimisations that would be impossible to spot using conventional methods.

Vergine explains: “We can now simulate, in some instances, thousands of different parameters all at the same time, and then find optimals across all of those parameters.” The result is a motor that is more efficient, lighter, cheaper, and uses fewer materials – critical factors in industries like automotive manufacturing, where cost pressures are intense.

A challenge worth solving

Redesigning motors at such a fundamental level has not been easy. “It has taken us at least a year to 18 months longer than we thought it would,” admits Vergine. “But that’s a double-edged sword. It proves just how hard what we are doing is, which makes it difficult for anyone else to copy.”

Despite the challenges, Monumo has, deservedly, reached an important milestone: “We hit minimum viable product in mid-2024, and we now have a fantastic customer pipeline.”

Monumo’s first market is automotive and, given the transition to electric and Net Zero goals, timing is everything. “The automotive sector is more competitive and in a much more disruptive state than it has been for probably 120 years,” Vergine notes. “The arrival of EVs, the rise of competition from Tesla and Chinese brands – companies that have historically been quite slow are now having to react very quickly and look at any opportunity to reduce cost.”

Monumo’s technology offers exactly that: “We are generally right now at around five to 10% of cost reduction,” says Vergine. “That doesn’t sound huge, but these are systems that have already had decades of innovation to reduce cost. So finding five or 10% that couldn’t be found otherwise is very, very valuable.”

To put that into perspective, a €500 motor produced in volumes of 10 million could see savings of up to €500 million.

Sustainability without compromise

But do Monumo’s cost reductions come at the expense of performance? The short answer is, no – in fact, they often enhance it. One of the biggest savings comes from reducing the use of rare earth materials. “We minimise the use of rare earth materials, which is permanent magnet material, which is by far the biggest cost in a motor. We can reduce it so that you only use what is absolutely essential, and that’s both very good environmentally and for the supply chain, but also for the ultimate cost,” Vergine explains. “At the moment, 80% of EVs use rare earth magnets. In 10 years’ time, I think that will be reversed – 80% will be magnet-free.”

Looking ahead

Monumo’s technology is still at the beginning of its journey, but Vergine has his eye on the future. “We expect over the next few years, our technology roadmap will do more and more.” One exciting avenue is energy generation: “We’re really looking forward to building a full system prototype for a generator that is cheaper, lighter, more reliable, and more efficient than what we see today,” says Vergine.

Whilst they aren’t at that stage yet, Vergine suggested that the company is also open to exploring recyclability as a potential area of optimisation in the future. “Factoring in recyclability as one of the optimisation areas is perfectly possible,” he says.

Deeptech’s impact

Deeptech AI is gaining traction and Vergine believes that it isn’t something that will only change creation and innovation – it will change the future of invention.

The story of Monumo is only just beginning – and as it continues to push against a century of tradition, it is already telling how deeptech has the power to transform industries where innovation has largely stood still.

In only three years and with £10 million in funding, Monumo is delivering results that companies with billions in turnover cannot match. That is the power of innovation, and it is why Monumo’s journey is only just starting.