3D Printing Is On The Rise And It's Not Hard To See Why

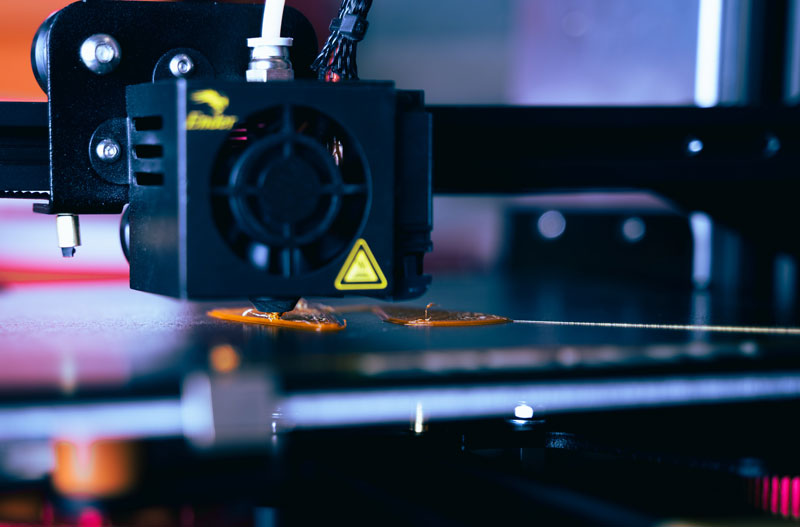

Just a few years ago, 3D printing was like what the blockchain was a decade ago. Not many knew about it, even fewer understood it, and its application to real-world problems wasn't very apparent. However, in the past decade, 3D printing has come a long way and 3D printers are becoming common bits of machinery employed by businesses and individuals.

As 3D printing technology has improved, it has become applicable in more diverse ways and more people have seen the value it has. Forecasts suggest that in just a few years, this is going to be an industry worth nearly $6bn. Here are some of the main reasons why 3D printing is growing in popularity.

Moulds

Moulds are used in the manufacturing process of a lot of products. Jewelry, tiles, plastic products, and even chocolate are made using moulds. Today, 3D printing can be done using a number of different materials which means different moulds can be made for different products. You can have food-grade plastic moulds to make edible products, or you can use high-temperature tolerant moulds to use for things like liquid metals. In the past, making the moulds was a difficult and time-consuming process, which meant the moulds were also extremely expensive.

With 3D printing, this takes only a few minutes. Businesses and individuals no longer need to rely on a specialist mould manufacturer. All they need is a 3D printer to do it themselves.

Customisation

If you buy a power tool, a watch, a mug, or any other kind of product, there is always some room for improvement to make it exactly according to your needs. For instance, if you want a shape that you can stick onto your phone's cover. In the past, this was close to impossible, but with online 3D printing, you can do this quite easily. If you have an elderly person that uses a cane and you would like to have a more ergonomic handle on the cane, you can print that using a 3D printer.

The fact that you can print these little bits and pieces that can be attached to other things opens up a whole new world of customisation. Today, there are several businesses that offer custom build parts for nearly any product

Instant Solutions

Businesses that are in the manufacturing industry are very sensitive to breakdowns in the production line. One breakdown can result in that entire production line coming to a standstill. By investing in just a single commercial 3D printer, they can manufacture pieces at any time and keep things going. Rather than waiting for days or even weeks for a little component to be shipped to them from a supplier, the 3D printer makes them self-reliant.

Modern 3D printers can print metal, plastic, silicone, and many other types of products. This helps a lot of businesses to stay online and manage their technical problems more effectively.

3D printing itself requires some expertise. You need the machine, but you also need to know how to operate the software and actually get the printed product. However, this is still a very small investment compared to the value that these machines provide. As 3D printing technology continues to advance, we are likely to see it implemented in more industries in the future.